Fuelish

Members-

Posts

24 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Events

Everything posted by Fuelish

-

Your setting a high standard to emulate, now its spring no excuse, will start my own tread as you suggested. Not as fortunate as you with garage space or even a proper garage. Seeing others progress does help with motivation

-

Well, here are my USA made shafts. Subaru inner MGTF outer and 415mm long. Not had a chance to try them as in the queue to have my rear hubs machined, that's another story because trying MGTF with discs first, under 15" wheels. The backup is the original rotoflex as per NJ.

-

Interesting BUT, in my view yours is better because of the larger wheel bearing and also no need to shim, this still requires that! PS - Now I have gone the Subaru diff route I have a pair of good second hand Volvo 340 Lobro 24mm 22 spline cv's including boots for what they cost me! So, if anyone is interested in doing your (NJ's) conversion....

-

Have you seen these on offer from Mark Field at Lemans https://www.ebay.co.uk/itm/Triumph-Gt6-Vitesse-roto-flex-cv-conversion-drive-shafts-1xpair/284154448390

-

Brief update with all bits ready for final assembly, shortened selector moves freely and shaft tube seal is glued back on with rubber solution. Not gone overboard with a super strong rear support but it is rigid, using one bolt hole and an original centre dowel to locate. Bracket needs a tidy and like to use Zinga to protect. Look forward to NJ's solution for an 'as original' position.

-

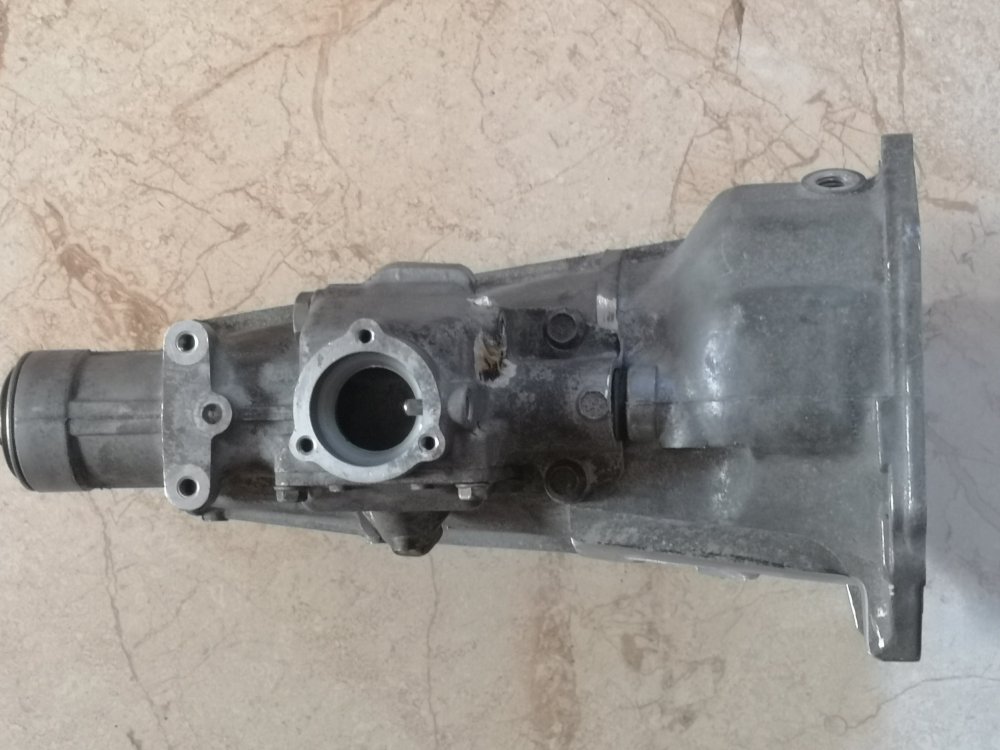

Subaru / Datsun Differential In Spitfire Rear Plate

Fuelish replied to wbrown53's topic in Drivetrain

-

Ah, the devil is in the detail, Ford cv's vs MGTF. The R100 shafts are 404mm iaw NJ. The guy in the US that is making my shafts uses Euro Escort cv's in Roto uprights and he makes his shafts approx. 17" (please do not use this as a factual figure) but, this ties in with your findings with Mazda 323 1.6 BH at 427mm. From SteveJM comments and zetecspit I'm hoping mine at 415mm with MGFT cv's will be correct. They are being made so time will tell!

-

I did follow your example and could have ground the top of the casing a little more and cut 2mm more off the front of the 'shifter' housing but for me a relatively disproportionate amount of work to gain 1/4". One thing I have been fortunate with is the seal on the rod tube; I managed to ease this off gently one end without damage. Now the tube is cut down to bridge the gap I can reuse the sleeve seal with some blue Hylomar or vulcanising glue. Have read you blog on moving the handbrake with interest. I have something planned here as trying to go for rear discs but want proof of concept before opening my mouth

-

Nick, nowhere near what you achieved to maintain the original position. This is what I managed today after picking up a Mk1 box and following Manana's example. Need to shorten the tube and selector shaft but, this slides freely. Need to make a rear support bracket but have shortened it 148mm (could make it 6" easily enough) which I think will be fine for me and it also means no major surgery to the handbrake position. Also ground away the side were the PFF mounts, think I will also mount it the using original holes again, as Manana. So much easier when you follow some one else's hard work - thanks both!

-

Damn! have paid for my custom shafts... I can only console myself with the fact they are 24mm 4340 48HRC. Appreciate the effort it takes to research, find and prove these things. As Nick has pointed out I think these 22mm Mazda BH 1.6 DOHC will be quite rare here in the UK. I'm sure purchasing and shipping from you would still be much cheaper Could you possibly give me some further consolation by an overall length of the BG axle, as you say it runs central to the Subaru cv cup and I've specified 415mm for mine?

-

Inspiring to see your excellent result as my car is in the 'page 1' condition only 3 years to go then Your car looks superb!

-

Hi Clive, sorry for the clanger, maybe I should stick to screen names! I appreciate any advice regarding the drive shaft length though. I'm looking at the best compromise between use and price as I have a complete restoration to consider. I have thought of using complete MGTF rear hubs so, I can fit discs. Sure this has been done before with R100 shafts. Other thoughts like custom lower wishbones, coil over springs instead of leaf with a short upper arm. Realistically I am aiming at a road car with 150bhp and 5 speed box. That's not to say in the distant future I cant upgrade but at least the back will cope and can be improved. I'm looking at running 195/50R15 tyres for traction so, not sure if increasing the rear track would require arches flaring as the kit from Steve for the conversion does lower the car about 1/2" as well.

-

Mk2 GT6 heated rear window

Fuelish replied to Bob Horner's topic in Triumph Spitfire / GT6 / Herald / Vitesse

Hi Bob, Not sure I understand the exact problem you have but, if it is of help and the connections are missing off the actual screen you can buy conductive silver epoxy which you can use to attach a spade terminal for the wire. you can also use it if you mask off carefully to repair individual broken element as they are normally on the surface and not embedded, as with modern heated glass. It's not cheap but available from RS or Farrnell but cheaper than another glass I suspect. I expect you have this well resolved by now! -

Hi Colin, thanks for the reply above but I also found this comment you made previously below: I know the volvo lobros don't have a lot of total plunge. The scooby ones have loads but looks like they will be running right at the ends. Almost considered getting a fresh snap-ring groove machined on the CV splines to get them a few mm further out the diff. Madness or genius? The reason for asking further is that the custom shafts I'm having made I am specifying 415mm over all length based on Nicks info the standard are 404mm. So, I know the R100 ones work but, whilst I have the option I have added 11mm does that make sense? Appreciate your thoughts.

-

I should resist making any comment on something I've not done myself, my remark was based on Steve's comment about his Fiesta shafts not my own experience. Please ignore me on this point . When I have received and tried mine custom made one's I'll share the info on supplier but I don't want to give anyone a bum steer unit I have proven them myself. This guy normally does the conversion for Escort hubs not MGF in GT6 uprights, the company are specialists for in race cars and drag cars. IMHO £400min. for a pair of drive shafts (just shaft) seemed expensive to me, when a complete axle replacement for a daily hack are under £100ea; I realise they are mass produced. The USA product is a bit cheaper and high quality but will depend on how much I get stung for import duties.

-

Second hand R100 drive shafts as you have all said, if found, are very expensive. So are the Mk1 Xr2. I made some enquiries in UK for custom made shafts and was horrified at prices from £200+ per side or £350 with new cv and stub axle! Searching the web I have found a company in the USA that has made similar kits for rotoflex cars but using Escort stub shafts in the uprights to Subaru diffs. Have given him some dimensions including the 415mm length and he has agreed to make them in the next 10 days and we are talking high grade! I will now await the UPS delivery along with Steve's package from OZ! Once I'm happy it all fits together I'll let everyone know the contact as he will have the proven pattern for MGF hubs... I am still also considering asking my local machine shop to shorten the Subaru drive shaft to 415mm and cut the 24mm 22 spline and nitride the end, if relatively cheap!

-

Have decided to 'bit the bullet' and have ordered the R160 conversion kit from steveJM, Australia. I checked my Subby inboard pots and they fit the (380mm) MGTF half shaft splines but given the rarity of R100 driveshafts I'm looking at the Fiesta option, which is what I understand steveJM has used on his EVspitfire. Has anyone else out there proved these on the road yet? Can anyone be more specific on the model/ year and excuse my ignorance but this is also the NSF as with R100? My final option would be to make custom shafts and from some comments read, they could possibly be 10mm longer using the Subby CV with the greater plunge depth?

-

Great, thank you both for sharing your experience. As mentioned I have the R160 diff, MG TF hubs and roto setup. Just ordered some 340 Lorbo's from NL. Either way; now I need to find some R100 half shafts or possibly cut and sleeve the longer shafts! I also have just been reading about the R160 conversion and if I have CV drive shafts, I don't necessarily need a modified back plate as can bolt in to the chassis slightly further forward. Would just have to maintain the leaf spring c/l when I make the platform . Will have to do some measuring to check feasibility. zetecspit, have you any posts on your conversion as not found yet,,, newbie!

-

Hi Nick, Regarding your conversion with Volvo 340 lorbo's, I have measured my MG TF short shaft and it is 380mm (24mm shorter than R100 you pictured). Is there any reason why you couldn't make the adaptor/spacer 39mm. I understand 'standard' is 15mm. Would there be some interference issue?

-

Hi rustbuckit2011, New to this forum, hello all. I am restoring a GT6 Mk3 '72 roto, this will be my 3rd GT6 restoration as well as a couple of previous Spitfires . This time I want to start with doing a better job on the suspension and drivetrain as looking at 150bhp engine. Have been reading with interest all info I can find. I have a R160 diff and MGTF hubs on standby and was vey interested to see you say you identified a drive shaft suitable for this. Would you mind sharing this info? My back up is to go for a Blackline LSD if I can find some of the short R100 shafts. Nick don't suppose you have any for sale?