flatter4

Members-

Posts

272 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Events

Everything posted by flatter4

-

When a mouse dies in our loft it stinks - that rat in the bathroom must have been real special!!!!

-

Peanut butter and all the other suggestions have been found to work at ours - so long as the other easy sources have dried up (next door's rabbit food). +1 for Zetec, they are cunning and sometimes 2 weeks needed, and use gloves as they will smell you on the cage / trap. I use a cage trap set on a hair trigger - and check it 2 + times a day to make sure nothing is in there suffering. Any rats are then drowned - not sure how humane any of it is, but drowning is pretty quick. I have caught rats with a spring type (oversized mouse trap) - but only after leaving in a dark chamber (old brick piled up) for >7 days.

-

Too right - complete fraudsters. ....added to the difficulty for young drivers is that they can't have TP driving other cars cover on their own insurance (as old fellas like me USUALLY get - but watch out some policies even exclude that for oldies.....)

-

Yep .... and remember the flasher circuit is on-off, and a cheap DC multimeter will get confused and average an oscillating voltage to show a low value. Use a test bulb.

-

...perhaps you mean you had swopped the coil and 'power' sides of the relay? Either way damned frustrating that you never got a run. Sympathy sent. Regards, Will.

-

John, need to see a wiring schematic to judge. Potentially if the fan is running it could act as a generator as the ignition is switched off and therefore feed back into the ignition circuit and keep the engine running. Some tests such as pulling a wire on the fan when the engine is "running on" could prove that. ....but as Monsieur Ecosse says, the obvious result is just that the fan runs backwards

-

The galling on the rocker arm bores is usually what scraps them. Bushing or replacement is the only solution

-

Tips can be refaced. They are chill cast, and the hardness goes 2mm or more deep. If you don't reface, be careful if using a flat blade feeler gauge as the feeler will bridge the wear and the gap will be the feeler gauge + the wear depth...... I use Chris Witor's shafts which seem to be nicely made and finished (I think tuftrided?)

-

Remember the temps have been stinking hot, so the oil will have been commensurately hotter - resulting in thinner oil, more losses and less pressure. It could be as simple as that

-

My son has played with this on a BMW E30. I think the parts commonly used (and affordable) come from either a Vauhaul Corsa or a Mercedes A class.

-

Once you've discounted that then look at the complex bits. Is there any balance pipe between front and rear carbs? Is it a standard 4:1 cast exhaust manifold?

-

I know it shouldn't be, but look at the ignition again. Sometimes things are counter-intuitive. Wet plugs / dry plugs, and optronic..... I know it's new, and I know it should be fine, but put the points back on - just to prove the point (no pun intended) I've had some very weird symptoms from a failing Lumention system. It was obviously carburation, rough idle, spitting back, wouldn't run without blipping the throttle. Obvious..... I ditched the electronics and put a set of points in and she ran beautifully.

-

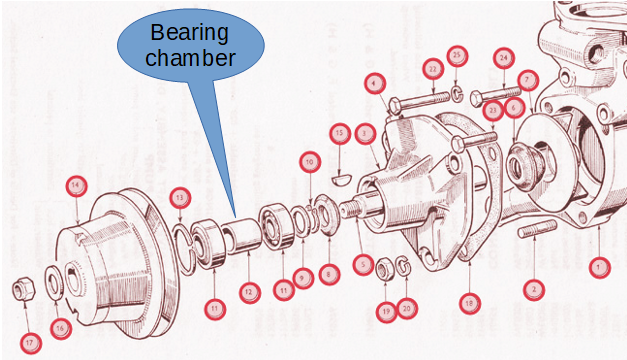

Water pump orientation and ports / tappings

flatter4 posted a topic in General Technical Discussions

Evening all. Water pumps...... It's a long time since I've seen a lovely old one with ports for greasing and other odd holes...... What do they all do? Should the weep chamber face downwards? Parts books tend to say yes, but I believed the science was that slight weeping was held in a chamber to allow evaporation - in which case it should be oriented upward to hold the water for evaporation (but then would fill with crap......) A. Is clearly the greasing point. I will blank this. B. is odd. I think this goes to the bearing chamber. From the sealing face there are 2 cross drillings 'aa' and 'bb'. They both seem to face forwards I'm guessing the instruction is to grease at point A until clean grease is expelled from point B? Given that the unit has been rebuilt with sealed for life bearings I think I can just blank both ports off? Thoughts please...... -

What a lovely machine. Well done. Have you done enough miles (smiles) to wear out a set of tyres yet !

-

...and as escadrille says, cam timing is not a problem, especially as it's a symmetric one. Follow advice on here and ask questions. Need to find an accurate tdc, and as advised, use a timing wheel (easy to print one if you want to save a few quid). Cheers, Will.

-

Jacob, I'm looking on my phone, so difficult to judge pics. Will look later on full screen. Yes dirt. Yes some wear. 50 psi on No.6 needs to be understood. Could be valve seating. Loose oil suction pipe is the one that worries me most. This could be the cause of your oil pressure fluctuation. Pump will suck air if it possibly can, and maybe when hot the pump was pulling air, noted as low oil pressure at idle. However it will also have pulled air at speed, air in oil systems is bad news. For a budget rebuild you might get away with polishing crank journals and new bearings? ....but need to understand the 50 psi

-

Oh no! With Nick all the way. Drain plug is horrid. You could cut the filter up to prove how bad it is, but it's not going to really help anything..... Risk of keeping running is that you take a usable crank into one needing a regrind ....but with fresh oil and filter you've given it best chances.....

-

....but hang on, I think the coil of the relay is across the north - south side of your relay diagram, so the sensor is a switch? - that closes (and earth's) when temperature is reached? In which case you have no means of overriding the control and putting the fan on early (or keeping on for cool down). Perhaps a 2 way switch? 1. On, and controlled by thermal switch 2. On permanently

-

John, good progress. Keep it up...... I think I understand what you're after with the additional lamp, and your diagram will give what you want (though strictly speaking it will show that the fan is being supplied with power (so should be running), rather than that it IS running. Semantics, but that's me) Don't forget some fuses!

-

Do the simple things first. New oil. New filter (use Bosch or Mann). Check /reseat the relief valve (tap with hammer, as grinding in is not a good idea unless engine is stripped to remove grinding paste). You can check the relief valve seating by using engineers blue, but difficult when everything is covered in oil. You could also temporarily shim the relief valve spring (find suitable washers), increasing the seating load may stop leakage and prove a bad seal here. Just keep revs low when the engine is cold to prevent overpressure.

-

Spitfire Front Shock absorbers

flatter4 replied to rogerguzzi's topic in Suspension, Handling, Tyres and Brakes

Daft pricing indeed. I use 3/8 spacers bought a decade (or two) ago for a sensible price. (GT6 with 330lb lowered springs - can't remember the Triumphtune No. but could look it up....) ...I'd be tempted to buy a singular 7/8 spacer and split it: to make 2 x 3/8" roughly quarter of the price of 2 x 3/8" -

^ I'm talking industrial Diesel engines and large construction equipment

-

You've definitely been spending these cold winter nights topping up your learning John ! We use the frequency gauges "Clavis gauge" (look them up). No idea how one gauge can be used on multiple belts sections, but they do work and give repeatable measurements - that are not influenced by the operator (or strength of their fingers). Really good for monitoring in development scenarios - to establish belt wear and life. ....but as said above, for most scenarios a skilled technician's judgement is good enough. Cheers, Will.

-

John, you need some more zeros...... modern common rail Diesels will run at over 2000 Bar = 29 000 PSI = 200 000 kPa If there's a leak in those systems it can do all sorts of damage: piecing skin, leak coming out as atomised - so ready to combust...... Even the pump - line nozzle systems will be typically 290 Bar at the injector nozzle (there is hydraulic amplification in the injector to raise the pumped pressure and lift the injector needle). Diesels are lovely things (espcially the industrial ones) - there's life in them yet!

-

Indeed the 'crush' on the shells keeps them in place (tags are only for assembly - especially important where it's necessary to align oil feed holes). Note you should also look at the back of the shells - any signs of fretting will be an indicator that the 'clamp' is not enough and the metal shell has been moving against the rod parent material. Unless you have some really good measuring kit (and measure at the right temperature) the appearance of the used parts is likely to be a better indicator of condition that a vernier picked up from the bottom of your tool box! I agree with the comments here - that 'resizing' is unnecessary. The only reason to do this is when someone has mixed the rod and cap halves up. You will then see out of round / steps and failed engines......