-

Posts

3,186 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Events

Everything posted by Escadrille Ecosse

-

Timing Chain Adjustment, Anyone?

Escadrille Ecosse replied to thebrookster's topic in General Discussions on anything

Yep! Same thought occurred to me too Do the new ones come with extra links for you to 'cut' to length like a bike? I suspect not. Serious chain that. Must be an interesting job getting it in and out of the chaincase. Must be even worse that trying to replace a tank track. -

Today I, Bollocks.....

Escadrille Ecosse replied to GT6MK3's topic in General Discussions on anything

That is a belter -

Today I, Bollocks.....

Escadrille Ecosse replied to GT6MK3's topic in General Discussions on anything

Always sobering when you are presented with the mortality of close contemporaries. But what a great spot to have a bench to share with folks. And good to have discovered it too -

Oil Filter Recommendations

Escadrille Ecosse replied to Escadrille Ecosse's topic in Engine and Ancillary talk

Thanks Nick, and Speedy. Three 916/1 for the Scimitar are on their way from Merlin. They were only £8.80 each which seemed very decent. -

Revolutions still use sleeve nuts. However if you give them a call they have lots of options available and very helpful. Sorted me out with replacements for the Scimitar recently.

-

Today I, Bollocks.....

Escadrille Ecosse replied to GT6MK3's topic in General Discussions on anything

Well today I had cause to open the non-recycling bin. Jesus wept, the smell.... Apparently my wife had found a dead rat at the back of the garden (!) so she put it in a plastic bag and dumped the thing in the bin. Unfortunately she failed to tie the bag closed and said rat it now pretty ripe. Another two weeks before that bin gets emptied. I suspect the whole street will be smelling it by then. -

-

Interesting YouTube channels

Escadrille Ecosse replied to egret's topic in General Discussions on anything

PU insulation board is often open cell, so yes it does rather soak up resin if used in the finished part rather than as a sealed mould. PU pattern/tooling board is closed cell and significantly more expensive (order of 4 to 5 times the price). The other thing that you can do if using either polyurethane OR polystyrene foams to make a single use mould is to cover it with a flexible release film like the stuff used when making pre-preg carbon parts. It's impervious to both epoxy and polyester resins and is thin and stretchy and can be stuck to the outside of the mould with spray-tack adhesive. Best used on a male mould so the film finish is on the inside of the part. This video shows how although they are using carbon fibre/epoxy the process is the same for polyester/glass. https://www.easycomposites.co.uk/learning/mouldless-composites-laminating -

Interesting YouTube channels

Escadrille Ecosse replied to egret's topic in General Discussions on anything

Nice video. Machining out that foam board is a significant task. I think that is PU insulation board and not polystyrene John. That is the 'standard' material for built up foam moulds because it doesn't dissolve in polyester resin. -

Andrew's Mk IV Spitfire

Escadrille Ecosse replied to egret's topic in Members Cars and Project threads

The Terry Wogan verion is rather 'different' from what I remember... are you allowed to use scissors? " and while I was there she showed me the little fir she'd been growing since she was a teenager and she let me trim it into an interesting shape with some scissors" This is what I remember from my schoolday in Aden, but as it was a long time ago and I was very young maybe I missed some of the plot -

Andrew's Mk IV Spitfire

Escadrille Ecosse replied to egret's topic in Members Cars and Project threads

Blimey, that wasn't yesterday. Flashback time! It was Janet and John for me though I think? Oh my, a very long time ago... -

This isn't VSCC but it is period. And looking back from where we are a different planet. There is a Herald in there too..

-

-

Like the pic of the Scimitar. Like you say they make a super tow car/camper. Don't have any of mine with the Spitfire on the trailer unfortunately but longest run with that combo was down to Anglesey in convoy with a couple of mates for a sprint weekend. 80mph plus (oops).

-

Oil Filter Recommendations

Escadrille Ecosse replied to Escadrille Ecosse's topic in Engine and Ancillary talk

Thanks Nick. I was sure there had been some discussion on this previously but blowed if I could find it -

Andrew's Mk IV Spitfire

Escadrille Ecosse replied to egret's topic in Members Cars and Project threads

Reading 5 by 5 John -

Need to restock on oil filters for the Scimitar. It uses the same GFE121/22/422 as fitted to the MGB and MGBGTV8. Current variety fitted is a TJ/QH which wouldn't be my first choice to be honest but the premium GFE22 Unipart filters are NLA. What would other recommend as a reputable brand?

-

Today I, Bollocks.....

Escadrille Ecosse replied to GT6MK3's topic in General Discussions on anything

@JohnD to avoid sidetracking Egret's thread to answer your question... "An aside: When I offered advice to egret, above, I tried to attract his attention by addressing him with "@egret", because when others do this the characters appear in the post in a blue cartouche, AND they get a 'notification', like that when someone quotes you. But it didn't work! How is this done, please?" Type @ and then start typing the name of the person you want to highlight and you will get a drop down list of individuals whose address starts with those letters. Do not put in any other characters, like the comma at the end of the name, or any spaces. If necessary wait until the dropdown appears so you can select the right recipient. -

Today I, Bollocks.....

Escadrille Ecosse replied to GT6MK3's topic in General Discussions on anything

Ahh, the dreaded catching the handle Only ever happens to the stuff you like.. -

Andrew's Mk IV Spitfire

Escadrille Ecosse replied to egret's topic in Members Cars and Project threads

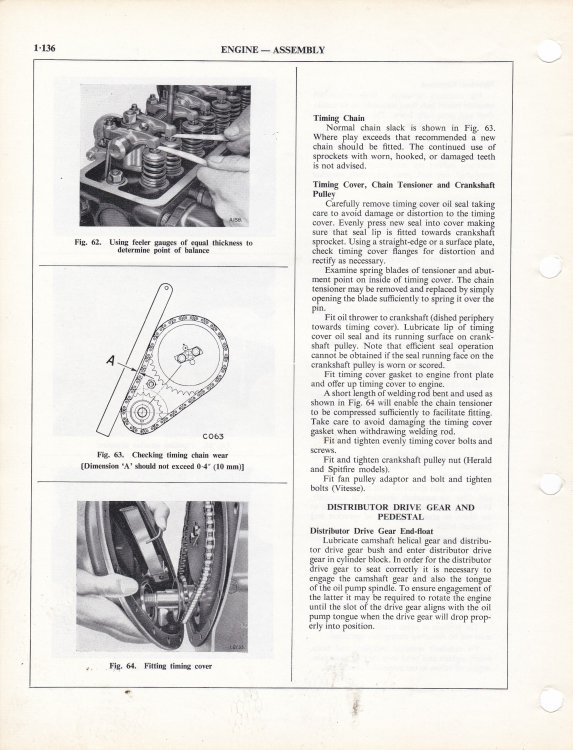

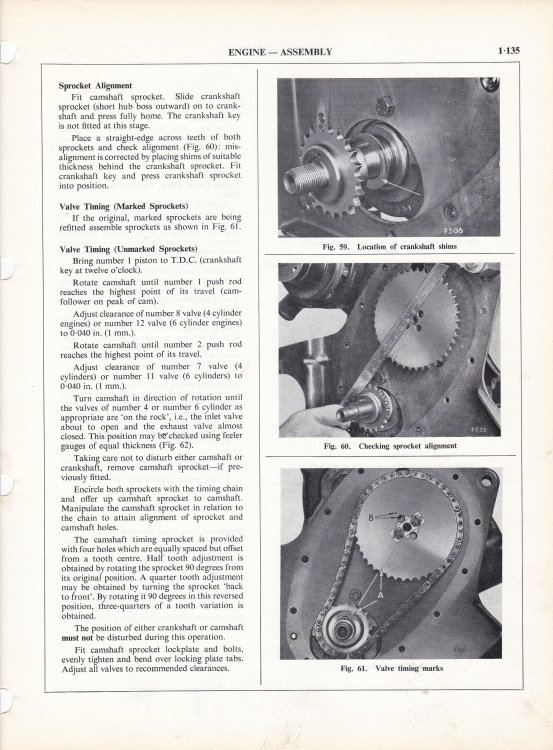

@egret asduming you are using the standard Spitfire single row chain then the camshaft gear is reversible so you can get within 1/2 a tooth. If it is a long way out then I doubt that it is a measurement problem. More likely a problem with the bolt up of the cam gear. But anyway. Regardless of what method you use you need to first set the engine to TDC with the timing chain OFF. Then with the chain still off and the timing gear losely bolted to tje cam so you can turn it easily set the cam to rock with the feeler gauges as per the manual. Then remove the cam gear put the chain on and hold the cam gear against the to see if you can get the bolts to line up to within half a hole. If not then rotate it 90 degrees in the chain and try again. Still out try another 90 degrees. If this doesn't get you close enough then remove the cam gear and turn it over, ie the face that was as the back is now at the front. Try to line up the bolt holes again. You should be within a half tooth of 'perfect'. This is the way I have done it many times with feeler gauges before I had the dial gauges. Personally I'm not keen on using piston stops through the plug, especially with the stop angled as it is on the Spitfire as it is very difficult to feel accurately when the piston contacts what with all the friction in there. The best/approved way is with the head off and a dial gauge on the crown of the piston. But as neither situation applies to you using the key on the nose of the crank will close enough here. I have never seen one that isn't close to spot on. -

Today I, Bollocks.....

Escadrille Ecosse replied to GT6MK3's topic in General Discussions on anything

-

-

Andrew's Mk IV Spitfire

Escadrille Ecosse replied to egret's topic in Members Cars and Project threads

If yours is any of the factory profiles or a symetrical aftermarket one ie inlet and exhaust have equal open close degrees, 22-62 62-22, 35-65 65-35, 40-80 80-40, etc then the method shown in the factory manual works fine. If it's asymetric like most of the Kent ones then this won't work. Helps if you have two sets of feeler gauges but I have in the past done it with one. Just a little more of a faff. The relevant pages from the workshop manual -

Today I, Bollocks.....

Escadrille Ecosse replied to GT6MK3's topic in General Discussions on anything

Good John. And Clive. One of the reasons I so much prefer Sideways. -

Today I, Bollocks.....

Escadrille Ecosse replied to GT6MK3's topic in General Discussions on anything

WTF!!